Hi Guys,

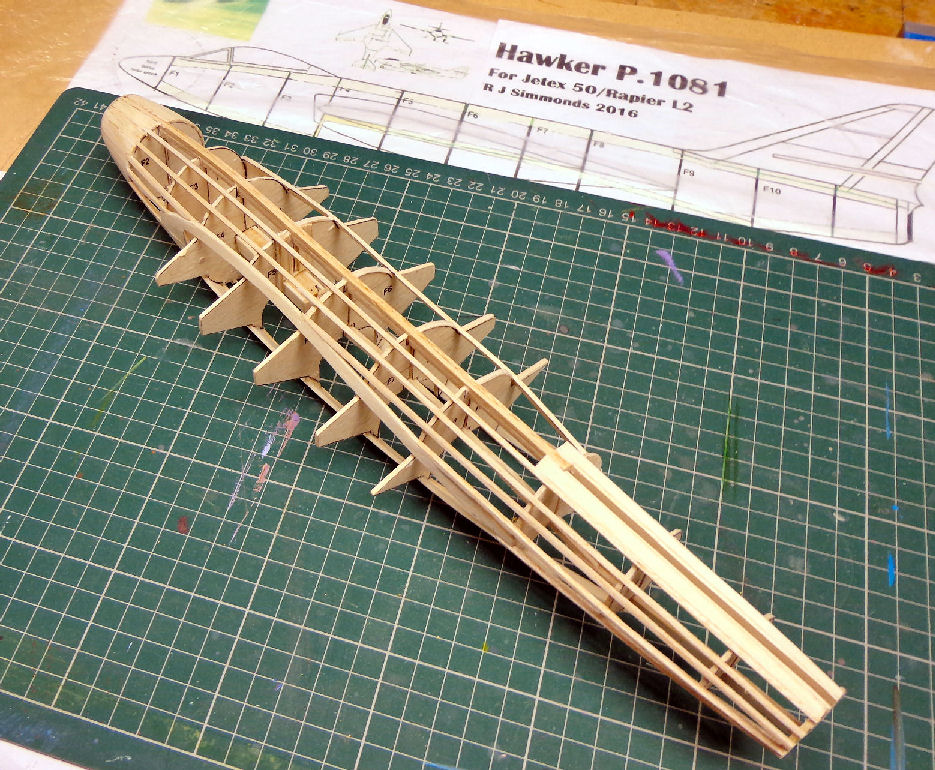

first, confession time. The stringered fuselage for the Hawker P 1081 didn't work out

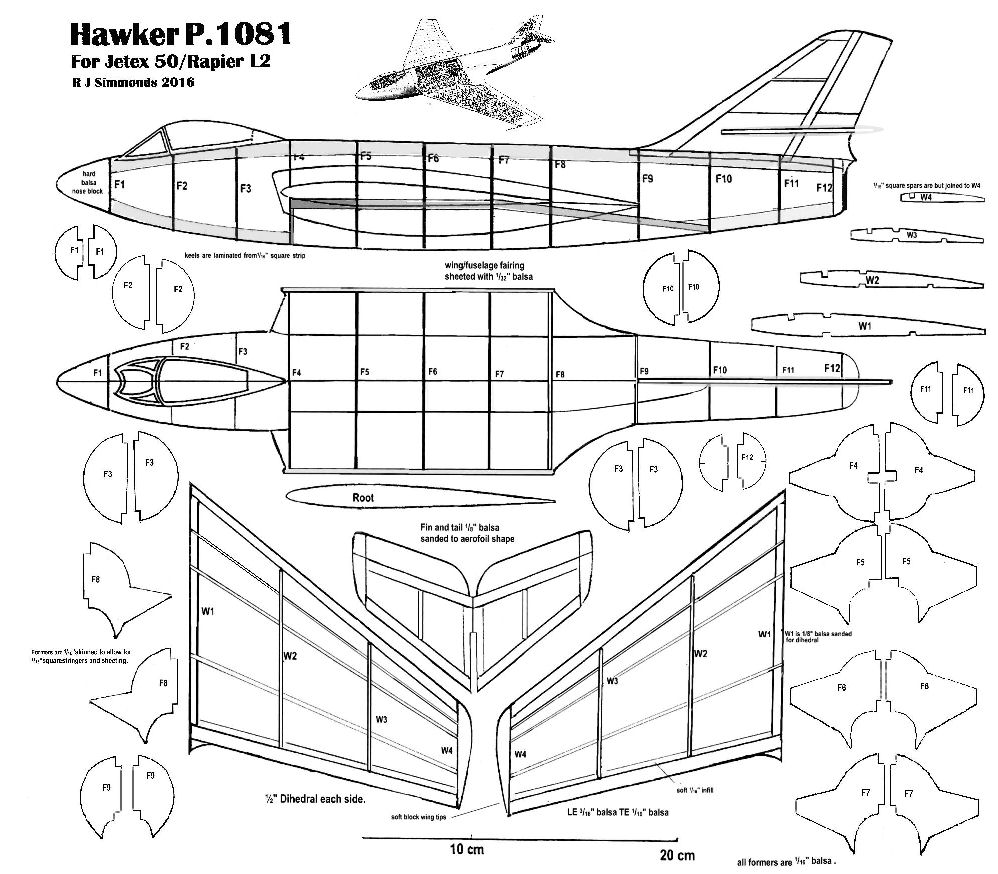

. The stringers were not as regular as I wold have liked and the whole thing was, at 15g, getting quite heavy. In frustration I decided to start again, with a moulded fuselage, that is, one without any stringers but an all-balsa shell like the Jetex Tailored models of yore. I have described the technique before (for a Draken) but here below is what I did for the P 1081.

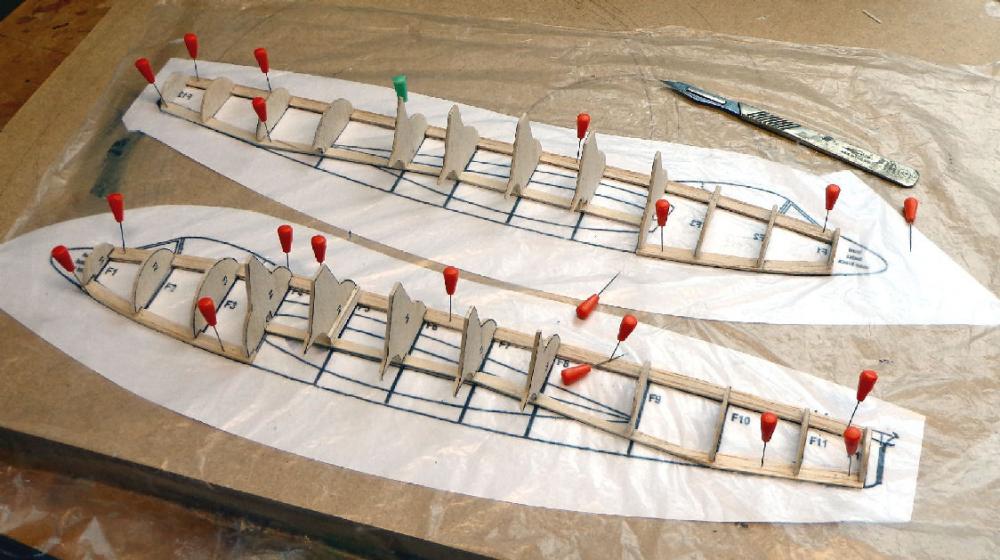

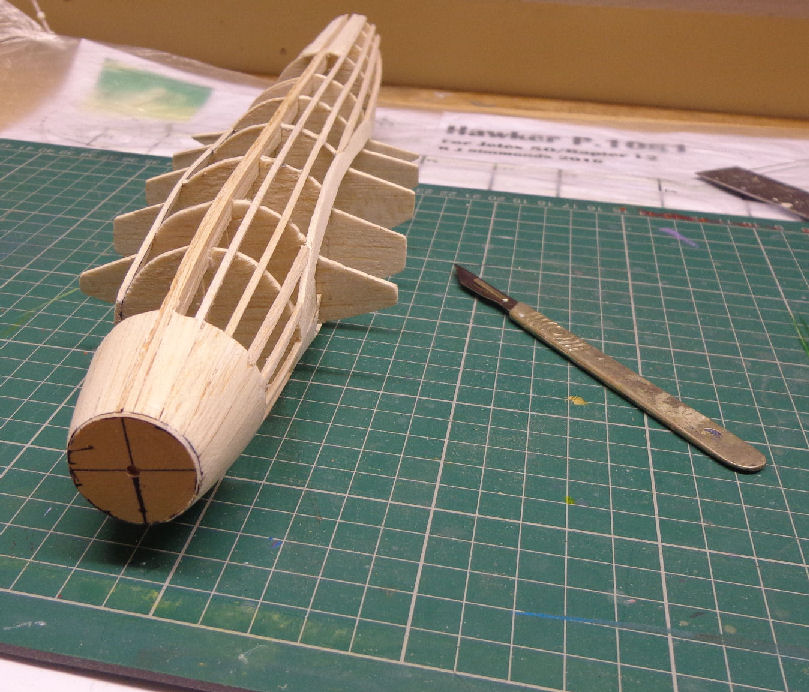

First, 1/32" plywood templates are made of the fuselage cross sections at regular (2-3" ) intervals and sandwiched between block balsa,

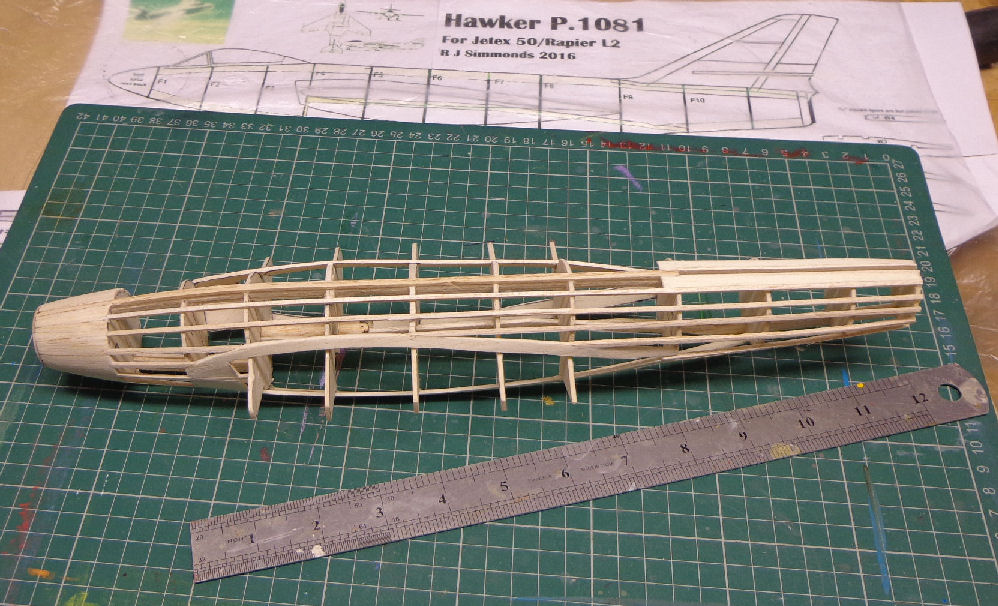

This is carved and sanded to shape and given two coats of epoxy resin. A really smooth finish is obtained with various grades of 'wet or dry' paper.:

The moulds are 'tack-glued' to 1/2" balsa before the nect step.

next, very soft 1/16" balsa is soaked in hot water for 2-3 hours:

The still wet balsa sheet is then wrapped around the mould and quite tightly bound with flat rubber strip"

Above: not a mummy taken from an ancient Egyptian tomb but the 1/16" balsa sheet tightly bound to the mould.

It is then left to dry for 12 hours (or so) in a warm place - say a radiator top.

When

completely dry the rubber is unwound and the shell carefully taken off the mould. The next bit is tricky: the shell is trimmed and pinned around the edges back on the mould and the surface wetted (hot water). Any slack in the shell is taken out by stretching over the mould and repinning. Hopefully, wetting the outer surface of the shell will remove the marks made by the rubber strip.

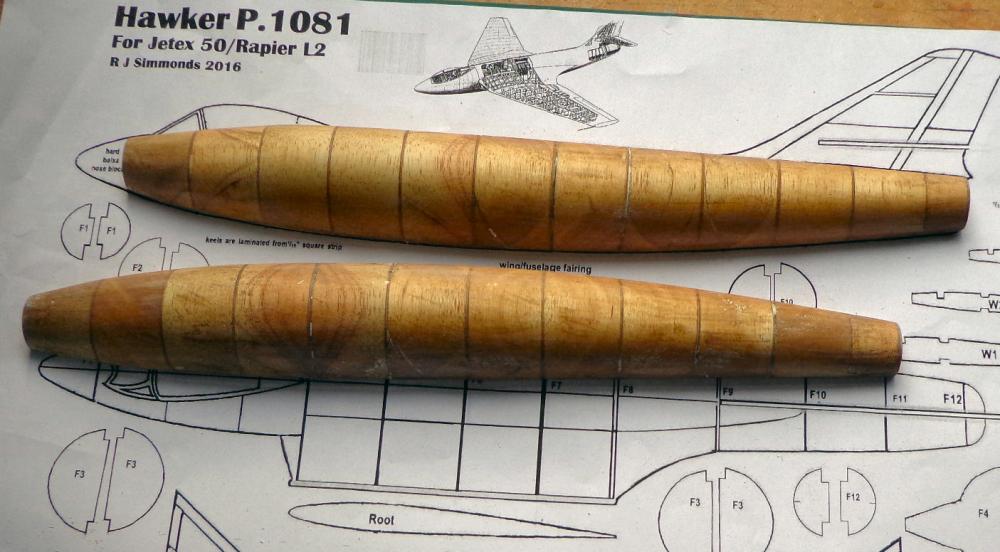

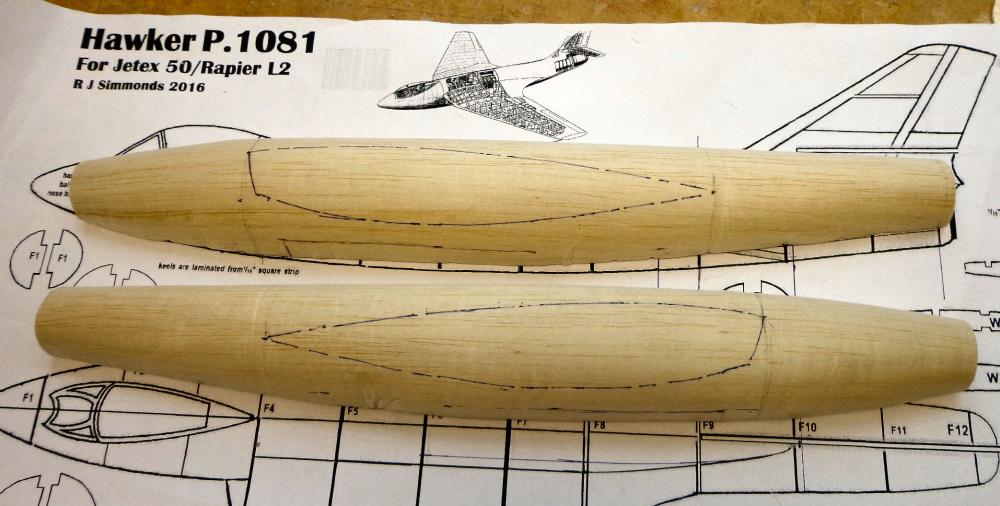

The whole is then left to dry completely. The near-perfect shell can then be taken off the mould and trimmed to shape:

Above: shells for the P 1081 fuselage. Some of the compound curves in the prototype are quite large, so the balsa did 'pinch' in places. Hopefully these can be sanded out later. The worst of these ( I should have cut in darts) are fortunately on the underside and will be cut away later for the motor trough

The shells weigh about 3.6g each - quite pleasing.

So this is some progress - next, making a fuselage frame the shells can be glued on to.