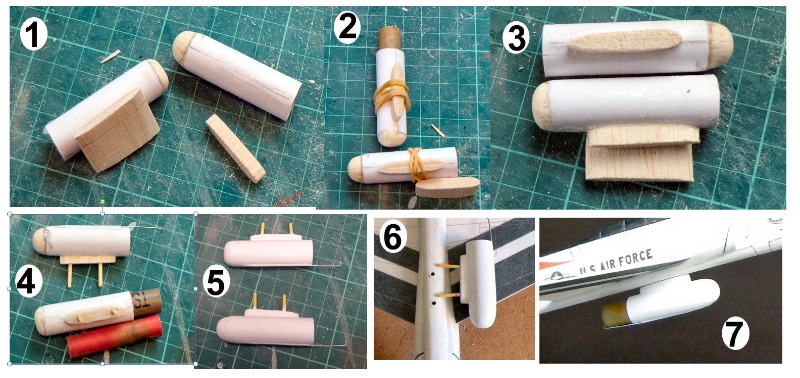

Though we intend to make a selection of jetex.org models again available as 'part kits', most of our designs, and the classic models of yesteryear, will be built from either templates or plans. So the builder will have to make their own motor mounts. A description of how I make them (other folk may do it differently) is therefore timely. The mount I describe will be for the Spectre L-2, for which, serendipitously, there is a sutable Estes motor tube that can be modified for our purposes.

1; the Estes motor tubes come in large (and long) packs that should last many years (I can supply suitable short lengths if required). I cut off about 3/4 the length of the motor.

2; 15 cm (or so) of 80 gsm printer paper is cut to the same width as your tube.

3; spread with PVA glue and wound tightly around the tube. Leave until completely dry.

4; the dry tubes are trimmed'

5; first stage complete - the tubes are now robust and ready for the next stage. I tend to make several at time. A used motor is useful to check the prepared tubes are still round and will fit!

1; light balsa, 5 mm (or so) thick is grooved (note my special 'grooving' tool) to fit the tube.

2; The tube is glued to the block, which is trimmed roughly to shape.

3; the fun bit. A drill bit is wrapped with masking tape to fit the tube so that you have, in effect, a lathe

(4) so that the end block can be symmetrically and enjoyably sanded to your desired shape

(5). Rounded or blunt - the choice is yours.

6;

6; two coats of 'Sand 'n' Seal' with rubbing down (still on the 'lathe') between coats completes this stage.